-

High Light

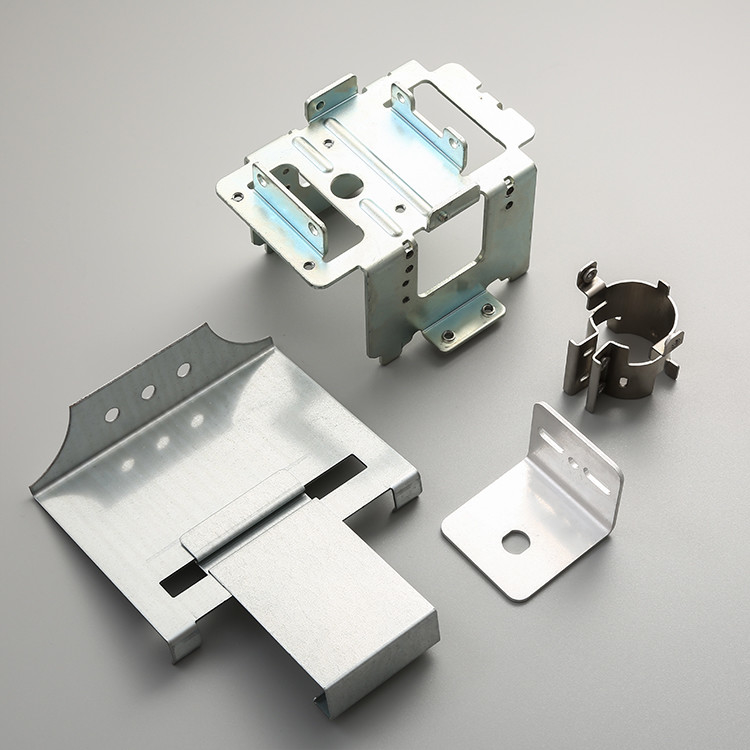

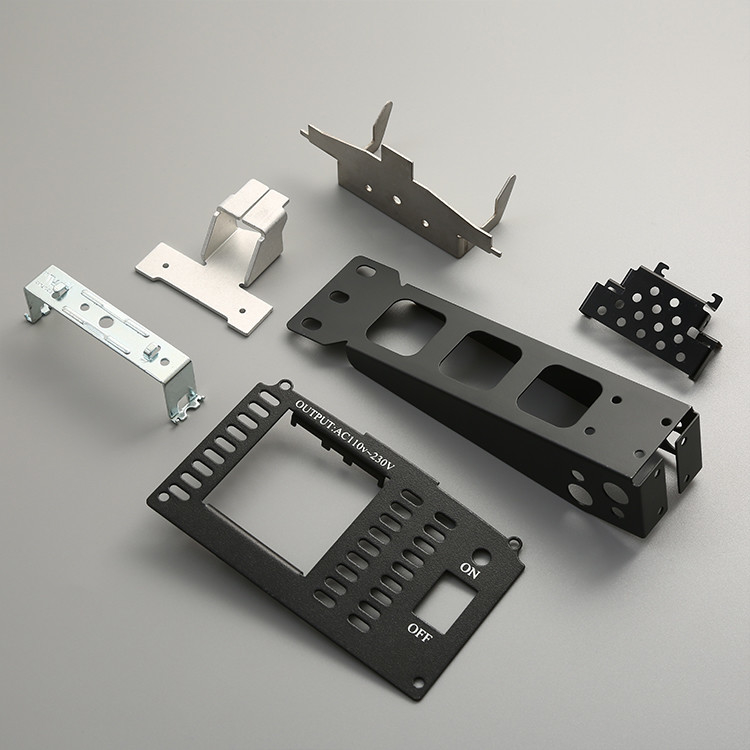

oem metal stamping parts

,no burrs sheet metal stamping parts

,oem sheet metal stamping parts

-

FeatureNo Burrs,anti Corrosion,no Deformation

-

ToolingIn-house

-

Brand NameProfessional OEM Service

-

CerticifationROHS Compliant

-

Test48H Salt-spray Testing

-

ExperienceOver 20 Years

-

Business TypeManufacturing Factory

-

Place of OriginChina

-

Brand NameProfessional OEM Service

-

CertificationROHS compliant

-

Model NumberSTP-A

-

Minimum Order Quantity1003pcs

-

PriceUSD0.07/piece

-

Packaging Detailsstamping supplies pressed sheet metal parts pressing metal components: PE Bag, Carton, Blister box, pallets, wooden case and so on, according to customers requirement.

-

Delivery Time17days

-

Payment TermsWestern Union

-

Supply Ability1000000 Piece/Pieces per Month

Custom Oem No Burrs Sheet Metal Stamping Parts

Custom OEM Sheet Metal Stamping Service Parts Sheet Metal White Stainless Steel Aluminum Small Components

| Tooling/Molding | Continuous Mold, Single Mold |

| Drawing Format | Auto CAD(IGS, STP, STL and X-T), DWG, PDF, Pro/Engineer, SolidWorks, etc |

| Materials | Spring Steel, Stainless Steel, Brass, etc |

| Thickness | 0.3 -1.2 mm |

| Surface Finish | Heat Treatment, Plating, Degreasing, Electrophoresis, etc |

| Tolerance | +/- 0.03 ~ +/-0.05 mm |

| Certificates | ISO 9001:2015, IATF 16949:2016, PPAP, ROHS, BV, CCC, etc |

| Supply Capacity | 600,000pcs ~1,000,000pcs / Week |

| Quality Control | 100% Inspection |

| Process | Custom Fabrication Based On Your Drawings |

| Project Solutions For |

Benz, BMW, Audi, IKEA, SIEMENS, Bosch, etc [Successfully Passed Factory Inspections of Many Well-Known Companies] |

![]()

![]()

![]()

Our company has strong R&D capability and develops many new products every year. In production, we strictly follow the ISO 9001 quality system to control quality and arrange production:

1. Don’t accept defective, strict inspection of supplier's raw materials.

2. Don’t manufacture defective, the production process is strictly controlled. For all products, the workers are strictly self-inspected on each machining process, and the quality inspectors do a regular inspection and spot inspection.

3. Don’t transferring defective, the defective products found in the previous process shall never be allowed to be transferred to the next process. Before shipment, the finished products shall be inspected again, and if any quality problems are found, and the products shall be reworked or rejected according to the relevant requirement.

If you want to get more, please visit the following Video.