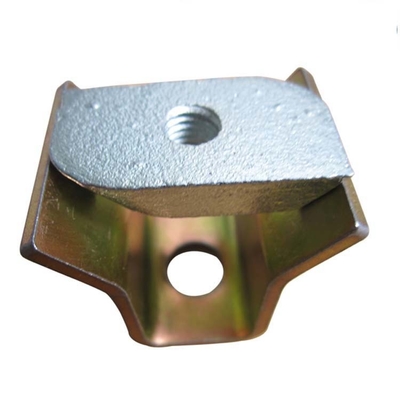

ANSI API BS Stamping 304 Stainless Steel Stamped Parts 0.5mm~12mm Thick

-

High Light

API BS Stamping 304 Stainless Steel

,ANSI Stamping 304 Stainless Steel

,304 Stainless Steel Stamped Parts

-

Product NameCustomized Stamping Parts

-

Color & SizeCustomized

-

Place Of OriginChina

-

MaterialSteel

-

Surface FinishSand Blasting

-

Place of OriginChina

-

Brand NameXCWY

-

Model NumberMSP-012

-

Minimum Order Quantity500 pieces

-

Price$3.00/ Piece

-

Packaging DetailsCustomize according to product situation

-

Delivery Time15-25

-

Payment TermsT/T, MoneyGram, Western Union

-

Supply Ability200000 Pieces per Month

ANSI API BS Stamping 304 Stainless Steel Stamped Parts 0.5mm~12mm Thick

OEM Stainless Steel Sheet Metal Fabrication Nonstandard Sheet Metal Fabrication Auto Sheet Metal Fabrication Parts

Metal Stamping Parts

Xincheng Stamping manufacturers steels parts to meet the needs of your specific applications. Whether you need is a large, heavy part that requires thick walls for support, a small, intricate part, or a part that requires hardening and finishing after stamping, Xincheng Stamping has the capabilities to assist you.

We offer progressive stamping, and prototype stampings to ensure you receive the stamping product that best first your industry needs.

Operation

- Bending - the material is deformed or bent along a straight line.

- Flanging - the material is bent along a curved line.

- Embossing - the material is stretched into a shallow depression. Used primarily for adding decorative patterns. See also Repoussé and chasing.

- Blanking - a piece is cut out of a sheet of the material, usually to make a blank for further processing.

- Coining - a pattern is compressed or squeezed into the material. Traditionally used to make coins.

- Drawing - the surface area of a blank is stretched into an alternate shape via controlled material flow. See also deep drawing.

- Stretching - the surface area of a blank is increased by tension, with no inward movement of the blank edge. Often used to make smooth auto body parts.

- Ironing - the material is squeezed and reduced in thickness along a vertical wall. Used for beverage cans and ammunition cartridge cases.

- Reducing/Necking - used to gradually reduce the diameter of the open end of a vessel or tube.

- Curling - deforming material into a tubular profile. Door hinges are a common example.

- Hemming - folding an edge over onto itself to add thickness. The edges of automobile doors are usually hemmed.

| Processed material | stainless steel, copper, carbon steel (according to customer's ) |

| Surface treatment | Hot galvanized, polishing, chrome/zinc/nickel plating, powder coating, anodize... |

| Making process | Laser cutting, Stamping, deep drawing,bending, punching ,threading, welding, tapping, riveting, grinding |

| Size | According to customer's designing & drawings |

| Thickness | 0.5mm ~12mm, or other special available |

| Standard | ANSI. API.BS.DIN.JIS.GB.etc |

| R&D | We support customer R&D make the file or improve the design if you needed |

| Inspection | IQC, IPQC,FQC,QA |

| Mould | Depend on customer's require to make the mould |

| Sample confirmation | Before start mass production we will send the pre-production samples to customer for confirmation.We will modify the mould until customer satisfied. |

| Products Scope | Funiture hardware, electronice hardware, construction hardware, sheet metal processing,machinery parts, hydraulic fitting |

| Packing | According to customer's requirements |

| Certificate | ISO 9001, ROHS |

![]()

![]()

We can design automation equipment according to customer's product type, which can be applied to all processes of our production, including stamping, injection molding and assembly. Through self-designed and manufactured automation devices, we can achieve mass production while ensuring the stability and consistency of parts.

Our servies

![]()

![]()